Danyang Kaixin Alloy Materials Co., Ltd. was founded on April 18th, 2007, covering an area of 13500 square meters with a registered capital of 20 million yuan. It is a professional enterprise engaged in independent production,research and development of high performance alloy materials such as precision alloy, high temperature alloy, nickel-based special welding wire, corrosion resistant alloy and so on. It is Jiangsu Province private science and technology enterprise, small and medium-sized technology-based enterprise, employee entrepreneurship base, Zhenjiang Harmony Enterprise, 2017 Jiangsu Top 100 high-tech enterprises with the most growth and 2020 South Jiangsu National Gazelle enterprise in Independent Innovation Demonstration Zone.

Our company will add the most advanced 3.5 tons vacuum melting furnace and 5 tons atmosphere protection electroslag furnace to expand 2 nickel-based welding wire production lines, improving the production capacity of the company greatly in 2023. At the same period, the expansion project with annual 2000 tons output of nickel-based welding materials has been started and will continue to increase R&D investment. Since 2020, our R&D investment has reached 10 million.

At present, we have cooperated with Beijing Steel Research Institute Nak to establish the "National Steel Material Testing Center - Joint Laboratory" and cooperated with Jiangsu Provincial Science and Technology to establish Zhenjiang Microwave Communication materials Engineering Center and Jiangsu (Kaixin) Nickel-based Superalloy Engineering Technology Research Center.

From 2022 to 2025, our company will gradually transform from civilian to military, from mass products to science and technology products, and gradually move to the ranks of "high, refined, sophisticated, specialized and special" production. To this end, we will combine the existing research and development, production, testing and etc advantages to continue to expand our research and development team, continuing to make progress from exploration and testing.

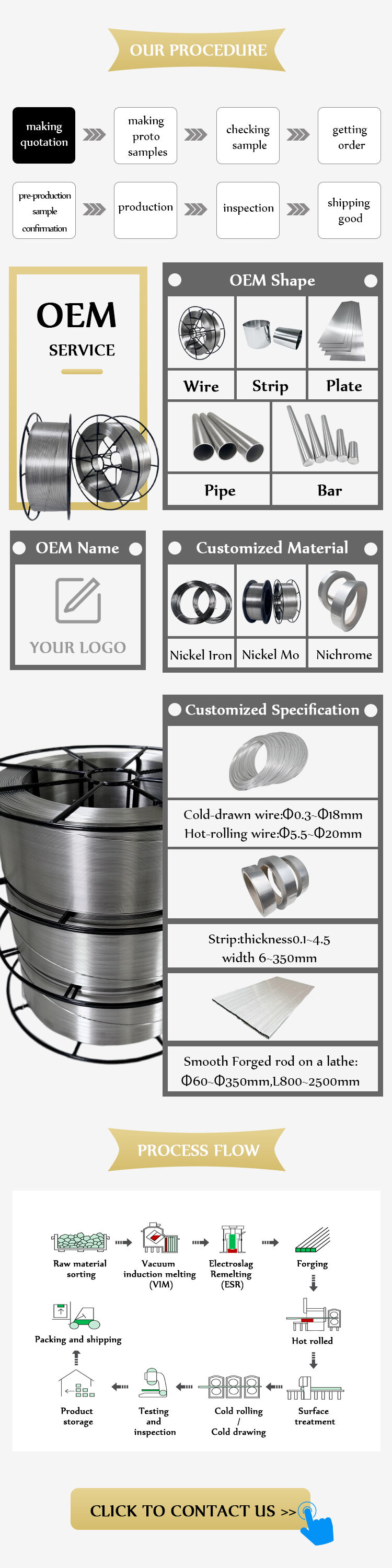

1、Accept customized products: Our existing 50kgs Vacuum induction furnace and 100kg electroslag remelting furnace can achieve new product development for our customers.

2、Attach great importance to site management, 6S has been successfully implemented for many years with high visualization degree and quality risk reduction;

3、We are the source factory with production and testing capabilities

4、We have passed ISO9001:2015 quality management system standard and our process is controllable

5、Our delivery time is controllable

6、Perfect after-sales service that each customer will have a special documentary personnel, who is responsible for communicating with customers, including delivery, quality, technology and other details.

1. Who are we?

Danyang Kaixin Alloy Materials Co., Ltd. is headquartered in Danyang, Jiangsu, China. It was established on April 18, 2007. It is an enterprise specializing in the independent production and research and development of high-performance alloy materials such as precision alloys, high-temperature alloys, and nickel-based welding wires.

2. What is your product range?

Mass production products (Inconel718, Inconel , GOST, GB/T standard materials. Most products have passed ROHS testing, and one of the Inconel625 welding wires has obtained ABS certification.

3. What are the advantages of price and quality?

We have our own production and inspection equipment. There are always pre-production samples before mass production, and there are always final inspections before shipment.

4. Do you provide samples?

Yes, we provide samples if needed, but customers need to pay the sample fee.

5. Can I visit your factory before ordering?

Of course, you are welcome to visit the factory.

KX-Alloy's AWS A5.14/A5.14M Nickel alloy 625 ERNiCrMo-3 welding cord Inconel alloy MIG Weld Cord invar 36 is the perfect remedy for any welding needs. This innovative item is made from premium quality nickel alloy, which is known for its excellent resistance to deterioration and high-temperature applications.

Specially designed to be used in the aerospace, chemical, and petrochemical sectors, since well like in various other sectors that require high-grade welding cord. Used advanced technology that ensures an outstanding weld and a normal, trusted efficiency.

Produced to provide excellent toughness, resilience and durability. It can be used in a variety of welding applications, consisting of welding of varied qualities of stainless-steel, carbon, reduced alloy, and high alloy steels.

The KX-Alloy's welding cord is easy to use, and it creates welds that are excellent minimal spatter, slag, and fumes. It provides feed ability is great and has a steady arc that enables the welder to have better control of the welding process. In addition, the cord consists of a surface area is smooth prevents it from jamming, which improves an individual's experience and efficiency.

Among the main top features is its excellent resistance to deterioration, production it appropriate to be used in severe settings. The cord can endure severe temperature levels and severe chemicals, which makes it a in shape is perfect aerospace, chemical, and petrochemical sectors.

KX-Alloy's welding cord is in addition highly affordable and is available in a variety of shapes and sizes to fit welding is various. It is packed in a spool is practical is very easy to handle, and it is also ensured to provide consistent outcomes.

You can trust KX-Alloy's AWS A5.14/A5.14M Nickel alloy 625 ERNiCrMo-3 welding cord Inconel alloy MIG Weld Cord invar 36 to deliver on its promise of superior welding items that fit the specific needs of various sectors. Obtain your own currently.