|

Alloy

|

%

|

Ni

|

Cr

|

Fe

|

Mo

|

Nb

|

Co

|

C

|

|

|

UNS N07718

|

Min

|

50

|

17

|

Rem

|

2.8

|

4.75

|

|||

|

Max

|

55

|

21

|

3.3

|

5.50

|

1.0

|

0.08

|

|||

|

Alloy

|

%

|

Mn

|

Si

|

S

|

Cu

|

Al

|

Ti

|

||

|

UNS N07718

|

Min

|

0.20

|

0.65

|

||||||

|

Max

|

0.35

|

0.35

|

0.015

|

0.30

|

0.80

|

1.15

|

|

Density

|

8.24/cm3

|

|

Melting Point

|

1260-1320℃

|

|

Magnetic Property

|

Nil

|

|

Fusing Temperature

|

1260℃~1320℃

|

|

Variety and Specification

|

Heat Treatment

|

Tensile Property

|

Hardness

|

Durability

|

||||||||||

|

MPa

|

MPa

|

%

|

MPa

|

r/h

|

%

|

|||||||||

|

Plate/Sheet/Strip

|

---

|

Anneal

|

≤895

|

≤485

|

≥40

|

HRB≤ 94

|

---

|

---

|

---

|

|||||

|

Plate/Sheet/Strip

|

≤ 0.25

|

Solid Solution

|

≤965

|

≤550

|

MV

|

HRB≤ 102

|

---

|

---

|

---

|

|||||

|

Plate/Sheet/Strip

|

>0.25~4.75

|

≤965

|

≤550

|

≥30

|

HRB≤ 102

|

---

|

---

|

---

|

||||||

|

Plate/Sheet/Strip

|

>4.75~25

|

≤1035

|

≤725

|

≥30

|

HRC≤ 25

|

---

|

---

|

---

|

||||||

|

Plate/Sheet/Strip

|

≤ 0.25

|

Standard

Heat Treatment

|

≥1240

|

≥1035

|

MV

|

HRC≤ 36

|

---

|

---

|

---

|

|||||

|

Plate/Sheet/Strip

|

>0.25~25

|

≥1240

|

≥1035

|

≥12

|

HRC≤ 36

|

---

|

---

|

---

|

||||||

|

Plate/Sheet/Strip

|

≤ 0.38

|

≥965

|

≥795

|

≥5

|

---

|

655

|

≥23

|

---

|

||||||

|

Plate/Sheet/Strip

|

>0.38~0.62

|

≥965

|

≥795

|

≥5

|

---

|

655

|

≥23

|

4

|

||||||

|

Plate/Sheet/Strip

|

>0.62~25

|

≥1000

|

≥825

|

≥5

|

---

|

690

|

≥23

|

4

|

||||||

|

Standard Number

|

Variety

|

Heat Treatment

|

℃

|

Tensile Property

|

||||||||

|

MPa

|

MPa

|

%

|

||||||||||

|

Q/3B 4052

|

Capillary Tube

|

Solid Solution

|

20

|

≤ 1070

|

≤ 655

|

≥ 30

|

||||||

|

Standard Heat Treatment

|

20

|

≥ 1275

|

≥ 1035

|

≥ 12

|

||||||||

|

Remark: The whole tube tensile specimen is used

|

||||||||||||

|

Standard Number

|

Variety

|

Heat Treatment

|

℃

|

Tensile Property

|

|||||||

|

MPa

|

MPa

|

%

|

%

|

||||||||

|

GJB 2611A

|

Cold Drawn Rod

|

Standard

Heat

Treatment

|

20

|

≥ 1270

|

≥ 1030

|

≥ 12

|

≥ 15

|

||||

|

650

|

≥ 1000

|

≥ 860

|

≥ 12

|

≥ 18

|

|||||||

|

GJB 3527

|

Cold Drawn Wire for Springs

|

20

|

≥ 1270

|

≥ 1035

|

≥ 12

|

--

|

|||||

|

Standard Number

|

Variety

|

Heat Treatment

|

℃

|

Hardness

|

Durability

|

||||||

|

GJB 2611A

|

Cold Drawn Rod

|

Standard

Heat

Treatment

|

20

|

MPa

|

r/h

|

%

|

|||||

|

650

|

HBW≥ 345

|

---

|

---

|

---

|

|||||||

|

GJB 3527

|

Cold Drawn Wire for Springs

|

20

|

---

|

690

|

≥ 23

|

≥ 4

|

|||||

|

Standard Number

|

Variety

|

Heat Treatment

|

℃

|

HBC≥ 32

|

---

|

---

|

---

|

||||

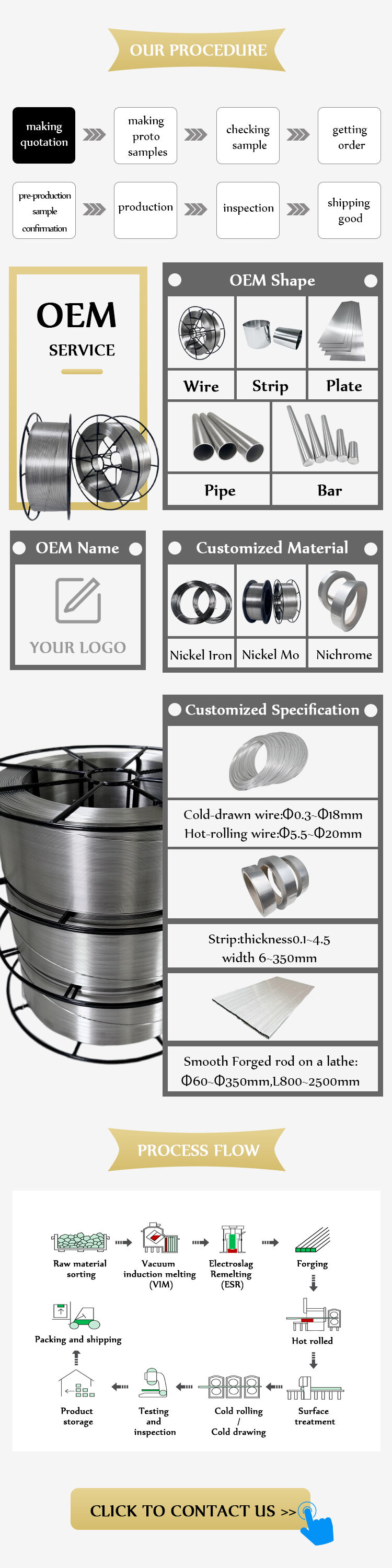

KX-Alloy is delighted towards offer its own newest product, the Ferronickel Alloy Astm F15 Invar 36 Rod Price 4J36 UNS k93600 Invar 36 Nickel Plate. This item is really a choice that's incredibly beneficial whoever requirements a dependable, resilient, as well as enduring alloy due to the tasks.

Ferronickel Alloy Astm F15 Invar 36 Rod Price 4J36 UNS k93600 Invar 36 Nickel Plate is a special alloy as well as is produced through integrating iron, nickel, and various other alloys. This distinct mix leads to an alloy which has a reduced coefficient of thermal growth, outstanding dimensional higher stamina, as well as safety. This creates it perfect for a selection of different markets aerospace this is definitely consisting of digital gadgets, as well as security.

Amongst the essential functions of this particular item is its own outstanding security dimensional that implies it is ideal for utilized in precision tools. Exactly just what this implies is it perfect for used in cryogenic as well as high-temperature requests it can easily preserve progressively its own form as well as dimension even if faced through severe problems. Additionally, the reduced coefficient of thermal growth using this alloy guarantees it extremely reliable it maintains its own design precise also likewise in difficult problems.

Another benefit of Ferronickel Alloy Astm F15 Invar 36 Rod Price 4J36 UNS k93600 Invar 36 Nickel Plate is it much a lot extra effective compared to lots of various other alloys, however still incredibly light-weight it has higher strength-to-weight proportion. This might enable it to become a selection of requests which have great resilience as well as stamina are incredibly essential however fat should be kept towards the extremely the very minimum, like in airplane manufacturing.

KX-Alloy's Ferronickel Alloy Astm F15 Invar 36 Rod Price 4J36 UNS k93600 Invar 36 Nickel Plate can easily likewise be corrosion-resistant, creating this perfect for utilize in severe atmospheres. The nickel material within the item withstands oxidation, creating it perfect for utilize in atmospheres which could be subjected towards the survive that's present.

Copyright © Danyang Kaixin Alloy Material Co., Ltd. All Rights Reserved - Privacy Policy - Blog