KX-Alloy

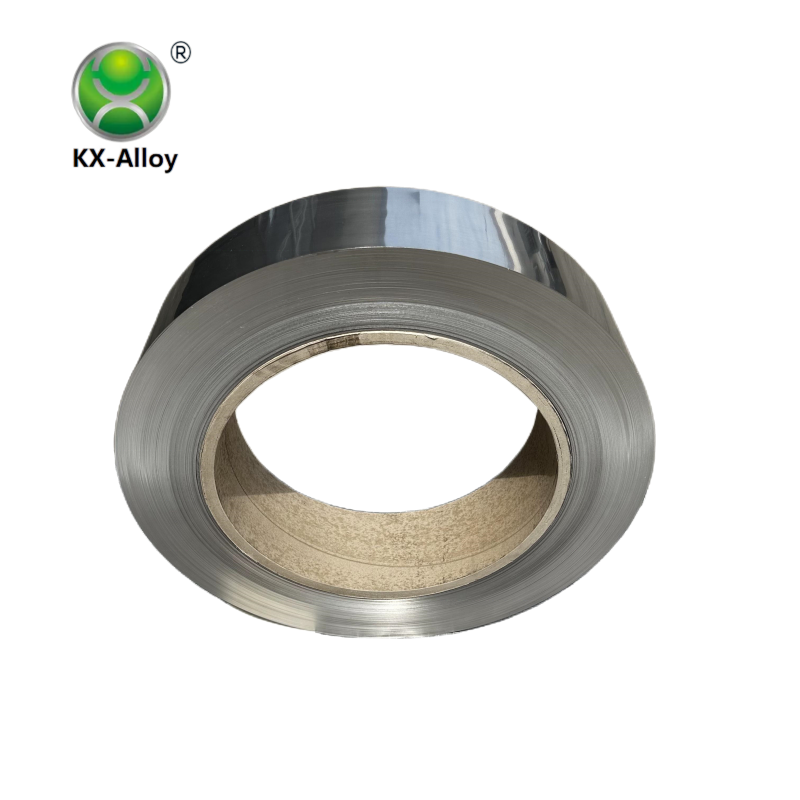

The Inconel 625 Sheet (UNS N06625) Is A Nickel-Based Superalloy with High Temperature and Corrosion Resistance is a item top-of-the-line boasts an outstanding amount of warm and corrosion opposition. Created from a superalloy nickel-based this sheet is built to resist probably the most challenging environmental conditions and meet with the numerous demanding applications. The item is graded as UNS N06625, an established industry standard and an assurance of quality.

Among the key features of the Inconel 625 Sheet (UNS N06625) Is A Nickel-Based Superalloy with High Temperature and Corrosion Resistance of KX-Alloy is its opposition impressive to. What this means is this technique may be used in a variety wide of this need materials that will withstand surroundings aggressive for example the petrochemical, aerospace, and nuclear organizations, amongst others. This sheet is a option wonderful both interior and applications outside contains excellent opposition to pitting and crevice corrosion.

In addition, the Inconel 625 Sheet (UNS N06625) Is A Nickel-Based Superalloy with High Temperature and Corrosion Resistance is engineered to withstand high conditions losing its properties being genuine. This may allow it to be a range popular numerous applications high-temperature such as furnace elements, heat exchangers, and fuel turbines. The sheet can withstand conditions starting from cryogenic to over 1000°F (540°C), making it an option versatile application.

A benefit being additional of KX-Alloy Inconel 625 sheet is its durability and strength. Its resistant to oxidation and will withstand repeated thermal biking without not sufficient properties technical. This can allow it to be an option great utilized in critical applications structural durability and power are vital. It's distinguished because of the high power and, at elevated conditions, its tiredness opposition helps it is perfect for use within high-stress applications.

The Inconel 625 Sheet (UNS N06625) Is A Nickel-Based Superalloy with High Temperature and Corrosion Resistance is an alternative anybody beneficial to a dependable, superior item that will withstand extreme ecological conditions. This sheet is a top-quality choice that won’t enable you to lower for high-temperature applications, aggressive environments, or high-stress structural applications whether you will need it. Give us a call at this right time to discover more in regards to the KX-Alloy Inconel 625 sheet its advantages being many.

Alloy |

% |

Ni |

Cr |

Mo |

Nb |

Fe |

Al |

Ti |

|

Min |

Rem |

20 |

8 |

3.15 |

|||||

Max |

23 |

10 |

4.15 |

5 |

0.4 |

0.4 |

|||

Alloy |

% |

C |

Mn |

Si |

Co |

P |

S |

||

Inconel 625 |

Min |

||||||||

Max |

0.1 |

0.5 |

0.5 |

1 |

0.015 |

0.015 |

Density |

8.44kg/m3 |

Melting point |

1290-1350℃ |

Magnetic Property |

Nil |

Standard Number |

Variety |

Heat Treatment |

Room-temperature Property |

||||||||||

MPa |

MPa |

% |

% |

Hardness |

|||||||||

≥ |

≤ |

||||||||||||

GJB 3165A

Liao Xin 7-0023

|

Hot rolled and forged rod |

(950~1030)℃/AC or WQ |

830 |

410 |

30 |

MV |

HB290 |

||||||

GJB 3317A |

Hot rolled plate |

(950~1030)℃/AC |

830 |

410 |

30 |

MV |

HV305 |

||||||

Liao Xin 7-0038 |

Cold rolled sheet

|

(950~1030)or(1090~1200)℃/AC |

830 |

410 |

30 |

-- |

HV305 |

||||||

Q/3B 4080 |

Pipe |

(960~1030)℃/AC or WQ |

825 |

415 |

35 |

-- |

HRC25 |

||||||

Standard Number |

Variety |

Heat Treatment |

815℃ Durability |

||||||||||

MPa |

r/h |

% |

|||||||||||

≥ |

|||||||||||||

GJB 3165A

Liao Xin 7-0023

|

Hot rolled and forged rod |

(950~1030)℃/AC or WQ |

114 |

23 |

15 |

||||||||

GJB 3317A |

Hot rolled plate |

(950~1030)℃/AC |

114 |

23 |

15 |

||||||||

Liao Xin 7-0038 |

Cold rolled sheet |

(950~1030)or(1090~1200)℃/AC |

114 |

23 |

15 |

||||||||

Q/3B 4080 |

Pipe |

(960~1030)℃/AC or WQ |

-- |

-- |

-- |

||||||||

1. Who are we?

We are based in Danyang, Jiangsu, China founded on Apr 18th, 2007, named Danyang Kaixin Alloy Materials Co., Ltd, which is a professional engaged in the independent production and R&D of high-performance alloy materials such as Precision Alloy, High-temperature Alloy, nickel-based welding wire and etc. high-performance alloy materials. We have more than 150 employees, including more than 20 research & development personnel and more than 25 management personnel. Our products are applicable to aerospace, Marine valves, ships, petroleum pipeline, power station desulfurization, communications electronics, Solar heat accumulation, new energy and etc. As a manufacturer, we always maintain the principle of quality first, and our products have begun to be quickly sold all over the world.

2. How can we guarantee quality?

We have our own production, inspection equipment and clear division of labor among functional departments;

We have passed ISO9001:2015 quality management system;

Establish joint laboratory with Beijing Steel research Nak with regular correction of inspection equipment and actively prepare for CNAS accreditation qualifications;

Raw material suppliers have been reviewed at multiple levels, including on-site audit, document audit, etc. to ensure the stability and reliability of raw materials quality;

Attach great importance to site management, 6S has been successfully implemented for many years with high visualization degree and quality risk reduction;

Always a pre-production sample before mass production;

Always final Inspection before shipment.

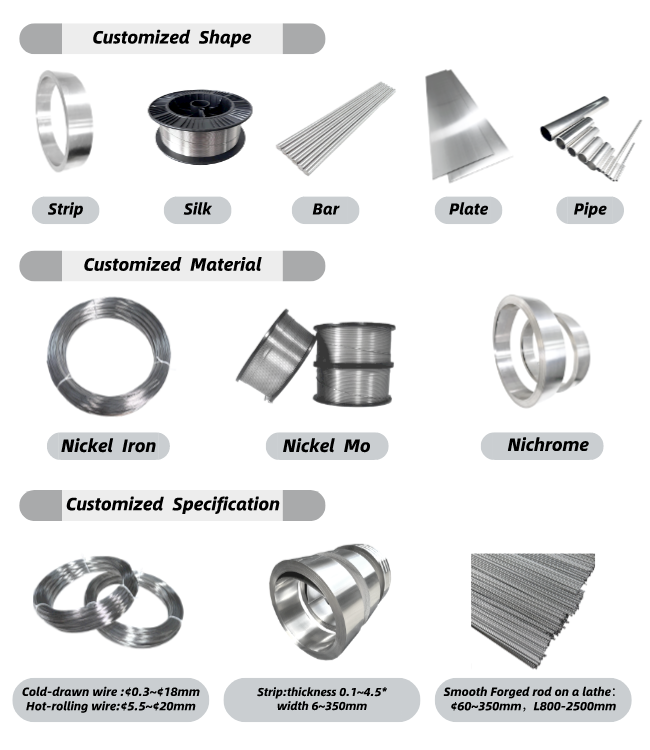

3. What can you buy from us?

Mass-production products(Inconel718,Inconel X-750,Inconel625,Inconel751,Hastelloy C276,HatelloyX,Nimonic80A,Kovar,Invar,Alloy42,ERNiCrMo-3,ERNiCrMo-4,NiFe55,NiFe60 ,ERNiCr-3,ERNiCu-7)from the production of standard materials which is in line with ASTM,GOST,GB/.Most products are ROHS tested and one of the Inconel625 welding wire has obtained ABS certification.

Accept customized products: Our existing 50kgs Vacuum induction furnace and 100kg electroslag remelting furnace can achieve new product development for our customers.

4. Why should you buy from us not from other suppliers?

①We are the source factory with production and testing capabilities

②We have passed ISO9001:2015 quality management system standard and our process is controllable

③Our delivery time is controllable

④Perfect after-sales service that each customer will have a special documentary personnel, who is responsible for communicating with customers, including delivery, quality, technology and other details.

5. What services can we provide?

Participate in and assist material application end anomaly analysis and improvement plan, such as poor welding, stamping cracking, deformation and etc. a series of back-end application problems.

We are proactive and responsive. General quality problems will be replied and dealt with on the same day, batch quality anomaly analysis report will be provided within three days, investigation and processing on-site will be arranged according to the actual situation.

Make full use of the technical team advantages according to the customer's use occasion to recommend more suitable products and make fewer detours for customers.

Accepted Delivery Terms: FOB, CFR, CIF, EXW, Express Delivery;

Accepted Payment Currency: USD, EUR;

Accepted Terms of Payment: T/T,MoneyGram, Credit Card, PayPal, Western Union;

Language Spoken: English, Chinese, Spanish, Japanese, German, Arabic, French, Russian, Korean, Italian.

Copyright © Danyang Kaixin Alloy Material Co., Ltd. All Rights Reserved - Privacy Policy - Blog