Alloy |

% |

Ni |

Cr |

Fe |

Mo |

Nb |

Co |

C |

Inconel 718 |

Min |

50 |

17 |

Rem |

2.8 |

4.75 |

||

Max |

55 |

21 |

3.3 |

5.50 |

1.0 |

0.08 |

||

Alloy |

% |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

Inconel 718 |

Min |

0.20 |

0.65 |

|||||

Max |

0.35 |

0.35 |

0.015 |

0.30 |

0.80 |

1.15 |

Density |

8.24/cm3 |

Melting Point |

1260-1320℃ |

Magnetic Property |

Nil |

Fusing Temperature |

1260℃~1320℃ |

Variety and Specification |

Heat Treatment |

Tensile Property |

Hardness |

Durability |

||||||||||

MPa |

MPa |

% |

MPa |

r/h |

% |

|||||||||

Plate/Sheet/Strip |

--- |

Anneal |

≤895 |

≤485 |

≥40 |

HRB≤ 94 |

--- |

--- |

--- |

|||||

Plate/Sheet/Strip |

≤ 0.25 |

Solid Solution |

≤965 |

≤550 |

MV |

HRB≤ 102 |

--- |

--- |

--- |

|||||

Plate/Sheet/Strip |

>0.25~4.75 |

≤965 |

≤550 |

≥30 |

HRB≤ 102 |

--- |

--- |

--- |

||||||

Plate/Sheet/Strip |

>4.75~25 |

≤1035 |

≤725 |

≥30 |

HRC≤ 25 |

--- |

--- |

--- |

||||||

Plate/Sheet/Strip |

≤ 0.25 |

Standard

Heat Treatment

|

≥1240 |

≥1035 |

MV |

HRC≤ 36 |

--- |

--- |

--- |

|||||

Plate/Sheet/Strip |

>0.25~25 |

≥1240 |

≥1035 |

≥12 |

HRC≤ 36 |

--- |

--- |

--- |

||||||

Plate/Sheet/Strip |

≤ 0.38 |

≥965 |

≥795 |

≥5 |

--- |

655 |

≥23 |

--- |

||||||

Plate/Sheet/Strip |

>0.38~0.62 |

≥965 |

≥795 |

≥5 |

--- |

655 |

≥23 |

4 |

||||||

Plate/Sheet/Strip |

>0.62~25 |

≥1000 |

≥825 |

≥5 |

--- |

690 |

≥23 |

4 |

||||||

Standard Number |

Variety |

Heat Treatment |

℃ |

Tensile Property |

||||||||

MPa |

MPa |

% |

||||||||||

Q/3B 4052 |

Capillary Tube |

Solid Solution |

20 |

≤ 1070 |

≤ 655 |

≥ 30 |

||||||

Standard Heat Treatment |

20 |

≥ 1275 |

≥ 1035 |

≥ 12 |

||||||||

Remark: The whole tube tensile specimen is used |

||||||||||||

Standard Number |

Variety |

Heat Treatment |

℃ |

Tensile Property |

|||||||

MPa |

MPa |

% |

% |

||||||||

GJB 2611A |

Cold Drawn Rod |

Standard

Heat

Treatment

|

20 |

≥ 1270 |

≥ 1030 |

≥ 12 |

≥ 15 |

||||

650 |

≥ 1000 |

≥ 860 |

≥ 12 |

≥ 18 |

|||||||

GJB 3527 |

Cold Drawn Wire for Springs |

20 |

≥ 1270 |

≥ 1035 |

≥ 12 |

-- |

|||||

Standard Number |

Variety |

Heat Treatment |

℃ |

Hardness |

Durability |

||||||

GJB 2611A |

Cold Drawn Rod |

Standard

Heat

Treatment

|

20 |

MPa |

r/h |

% |

|||||

650 |

HBW≥ 345 |

--- |

--- |

--- |

|||||||

GJB 3527 |

Cold Drawn Wire for Springs |

20 |

--- |

690 |

≥ 23 |

≥ 4 |

|||||

Standard Number |

Variety |

Heat Treatment |

℃ |

HBC≥ 32 |

--- |

--- |

--- |

||||

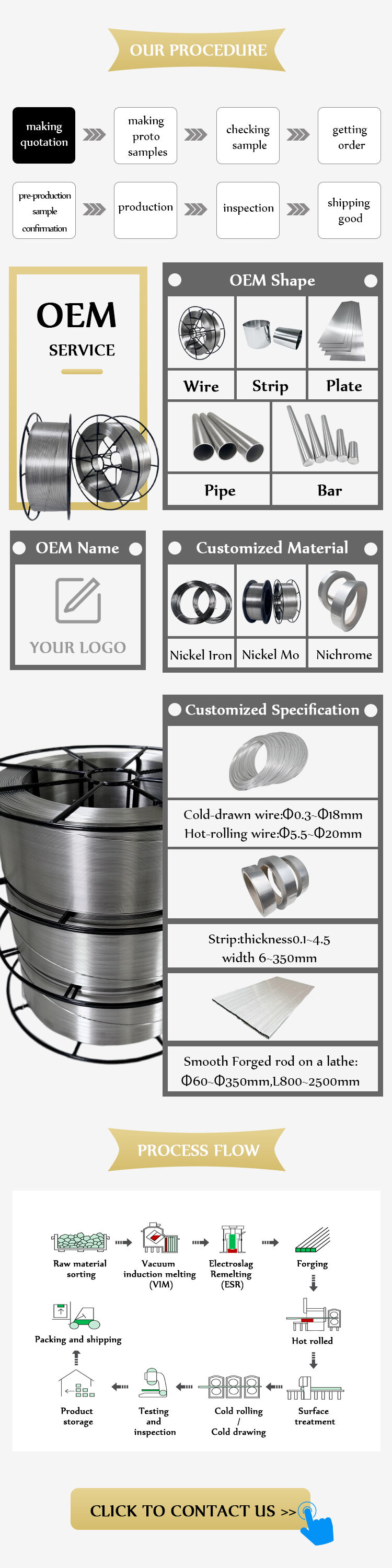

KX ALLOY

The Pure Nickel Monel Hastelloy Inconel 600 Steel Bar/Rod Alloy 601 Round Bar Inconel 718 is an item that is top-of-the-line the metal alloy industry. Built from the product quality metals and that can be greatest, this bar/rod alloy features a finish that is flawless durability that's the best.

Pure Nickel Monel Hastelloy Inconel 600 Steel Bar/Rod Alloy 601 Round Bar Inconel 718 is great for applications that want power and resilience. It's widely used in the aerospace industry, chemical processing plants, and petroleum refineries because of its resistance this is certainly great to and surroundings that are high-temperature.

KX-Alloy's Pure Nickel Monel Hastelloy Inconel 600 Steel Bar/Rod Alloy 601 Round Bar Inconel 718 is manufactured out of an original blend of nickel, chromium, iron, copper, and molybdenum to present the security this is certainly corrosion that is ultimate. This enables the alloy to withstand the most surroundings which are extreme including high-pressure circumstances and saltwater environments.

Along side its opposition to corrosion, KX-Alloy's Pure Nickel Monel Hastelloy Inconel 600 Steel Bar/Rod Alloy 601 Round Bar Inconel 718 is likewise resistant to oxidation, rendering it an choice that is ideal applications that want high-temperature stability and durability.

Furthermore, this bar/rod alloy is easy to complete business with, enabling machining that is excellent fabrication. It may be welded, brazed, and soldered with ease, making this a choice that is ideal applications that require intricate forms and styles.

At KX-Alloy, we take pride in providing the best-quality items at the essential costs that can be competitive. Our Pure Nickel Monel Hastelloy Inconel 600 Steel Bar/Rod Alloy 601 Round Bar Inconel 718 is not any exclusion. We provide this system at a high price point that is affordable, without the need to sacrifice some of the durability and quality that you expect from KX-Alloy.

To sum up, then KX-Alloy's Pure Nickel Monel Hastelloy Inconel 600 Steel Bar/Rod Alloy 601 Round Bar Inconel 718 may be the perfect product for you personally if you require a metal bar/rod alloy that is very easy to utilize, very resistant to corrosion and oxidation, and that can withstand extreme conditions and pressure. E-mail us to find out more about our items and exactly how we can help you find the answer that is ideal your project requires today.

Copyright © Danyang Kaixin Alloy Material Co., Ltd. All Rights Reserved - Privacy Policy - Blog