Alloy |

% |

Ni |

Cr |

Fe |

Mo |

Nb |

Co |

C |

Inconel 718 |

Min |

50 |

17 |

Rem |

2.8 |

4.75 |

||

Max |

55 |

21 |

3.3 |

5.50 |

1.0 |

0.08 |

||

Alloy |

% |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

Inconel 718 |

Min |

0.20 |

0.65 |

|||||

Max |

0.35 |

0.35 |

0.015 |

0.30 |

0.80 |

1.15 |

Density |

8.24/cm3 |

Melting Point |

1260-1320℃ |

Magnetic Property |

Nil |

Fusing Temperature |

1260℃~1320℃ |

Variety and Specification |

Heat Treatment |

Tensile Property |

Hardness |

Durability |

||||||||||

MPa |

MPa |

% |

MPa |

r/h |

% |

|||||||||

Plate/Sheet/Strip |

--- |

Anneal |

≤895 |

≤485 |

≥40 |

HRB≤ 94 |

--- |

--- |

--- |

|||||

Plate/Sheet/Strip |

≤ 0.25 |

Solid Solution |

≤965 |

≤550 |

MV |

HRB≤ 102 |

--- |

--- |

--- |

|||||

Plate/Sheet/Strip |

>0.25~4.75 |

≤965 |

≤550 |

≥30 |

HRB≤ 102 |

--- |

--- |

--- |

||||||

Plate/Sheet/Strip |

>4.75~25 |

≤1035 |

≤725 |

≥30 |

HRC≤ 25 |

--- |

--- |

--- |

||||||

Plate/Sheet/Strip |

≤ 0.25 |

Standard

Heat Treatment

|

≥1240 |

≥1035 |

MV |

HRC≤ 36 |

--- |

--- |

--- |

|||||

Plate/Sheet/Strip |

>0.25~25 |

≥1240 |

≥1035 |

≥12 |

HRC≤ 36 |

--- |

--- |

--- |

||||||

Plate/Sheet/Strip |

≤ 0.38 |

≥965 |

≥795 |

≥5 |

--- |

655 |

≥23 |

--- |

||||||

Plate/Sheet/Strip |

>0.38~0.62 |

≥965 |

≥795 |

≥5 |

--- |

655 |

≥23 |

4 |

||||||

Plate/Sheet/Strip |

>0.62~25 |

≥1000 |

≥825 |

≥5 |

--- |

690 |

≥23 |

4 |

||||||

Standard Number |

Variety |

Heat Treatment |

℃ |

Tensile Property |

||||||||

MPa |

MPa |

% |

||||||||||

Q/3B 4052 |

Capillary Tube |

Solid Solution |

20 |

≤ 1070 |

≤ 655 |

≥ 30 |

||||||

Standard Heat Treatment |

20 |

≥ 1275 |

≥ 1035 |

≥ 12 |

||||||||

Remark: The whole tube tensile specimen is used |

||||||||||||

Standard Number |

Variety |

Heat Treatment |

℃ |

Tensile Property |

|||||||

MPa |

MPa |

% |

% |

||||||||

GJB 2611A |

Cold Drawn Rod |

Standard

Heat

Treatment

|

20 |

≥ 1270 |

≥ 1030 |

≥ 12 |

≥ 15 |

||||

650 |

≥ 1000 |

≥ 860 |

≥ 12 |

≥ 18 |

|||||||

GJB 3527 |

Cold Drawn Wire for Springs |

20 |

≥ 1270 |

≥ 1035 |

≥ 12 |

-- |

|||||

Standard Number |

Variety |

Heat Treatment |

℃ |

Hardness |

Durability |

||||||

GJB 2611A |

Cold Drawn Rod |

Standard

Heat

Treatment

|

20 |

MPa |

r/h |

% |

|||||

650 |

HBW≥ 345 |

--- |

--- |

--- |

|||||||

GJB 3527 |

Cold Drawn Wire for Springs |

20 |

--- |

690 |

≥ 23 |

≥ 4 |

|||||

Standard Number |

Variety |

Heat Treatment |

℃ |

HBC≥ 32 |

--- |

--- |

--- |

||||

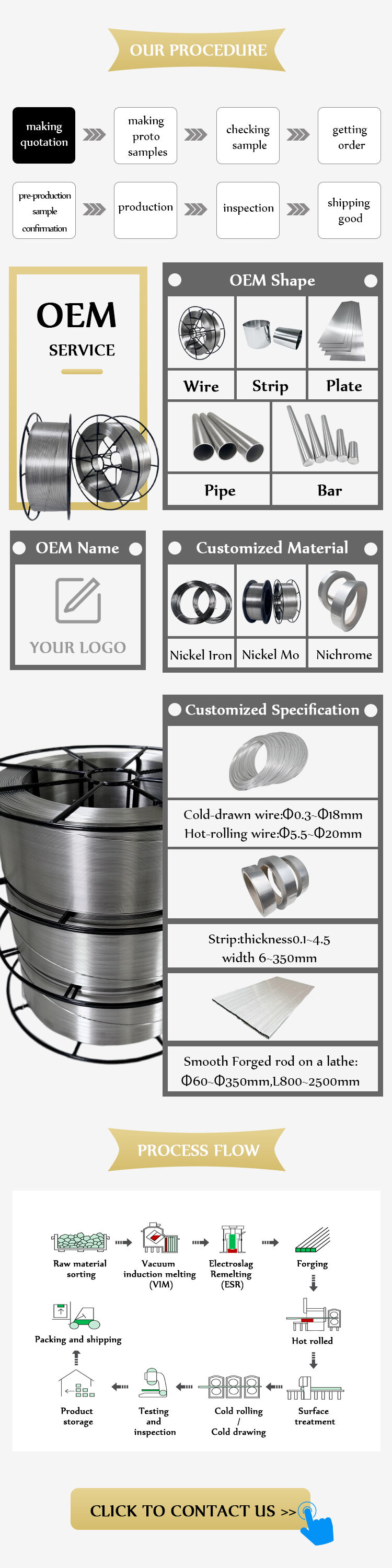

KX-Alloy

Is happy towards present our costs UNS N07718 GH4169 Inconel 718 line of product, that includes springtime cable, rounded lawyers, bit, tube, steel sheet, illumination pole, natural nickel choices. Our Inconel 718 items are created coming from a mix of nickel, chromium, molybdenum, providing outstanding protection towards higher rust temperature levels. This high-performing products is frequently utilized in markets like aerospace, oils chemical handling, fuel.

Among the much a lot extra outstanding choices that include this is their resilience is remarkable. Can easily withstands temperature level is severe towards 1300°C (2372°F) without shedding its own architectural stability or even ending up being fragile, creating it a suitable option for high-temperature requests. Its own protection towards oxidation rust guarantees that our items will certainly maintain their high top premium in time, reducing the requirement for substitutes or even repair work.

Deal amazing flexibility, their kinds that will certainly differ all of them appropriate for different requests. For example, the springtime cable television is perfect for springtimes that runs in incredibly higher problems or even destructive atmospheres, although bench ideal for elements along with higher technical stamina demands. The bit steel sheets options are ideal for production small components, while television choices is finest fit towards warm exchangers move is liquid. Lastly, the illumination pole nickel is natural are typically discovered in brazing requests welding.

At KX-Alloy, our team recognize that expense could be an element is essential selecting products for your job is why our team have guaranteed that our UNS N07718 GH4169 Inconel 718 items are valued competitively, without compromising efficiency or even high top premium. You can easily depend on our items towards provides the worths is finest for your cash while guaranteeing that the elements will certainly does efficiently reliably.

If you desire dependable, resilient, top quality UNS N07718 GH4169 Inconel 718 items, look no more compared to KX-Alloy. Along with our dedication towards affordable prices remarkable efficiencies, you can easily count on that you will be creating a smart financial assets in your job when you select KX-Alloy.

Copyright © Danyang Kaixin Alloy Material Co., Ltd. All Rights Reserved - Privacy Policy - Blog