Alloy |

% |

Ni |

Cr |

Fe |

Mo |

Nb |

Co |

C |

Inconel 718 |

Min |

50 |

17 |

Rem |

2.8 |

4.75 |

||

Max |

55 |

21 |

3.3 |

5.50 |

1.0 |

0.08 |

||

Alloy |

% |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

Inconel 718 |

Min |

0.20 |

0.65 |

|||||

Max |

0.35 |

0.35 |

0.015 |

0.30 |

0.80 |

1.15 |

Density |

8.24/cm3 |

Melting Point |

1260-1320℃ |

Magnetic Property |

Nil |

Fusing Temperature |

1260℃~1320℃ |

Variety and Specification |

Heat Treatment |

Tensile Property |

Hardness |

Durability |

||||||||||

MPa |

MPa |

% |

MPa |

r/h |

% |

|||||||||

Plate/Sheet/Strip |

--- |

Anneal |

≤895 |

≤485 |

≥40 |

HRB≤ 94 |

--- |

--- |

--- |

|||||

Plate/Sheet/Strip |

≤ 0.25 |

Solid Solution |

≤965 |

≤550 |

MV |

HRB≤ 102 |

--- |

--- |

--- |

|||||

Plate/Sheet/Strip |

>0.25~4.75 |

≤965 |

≤550 |

≥30 |

HRB≤ 102 |

--- |

--- |

--- |

||||||

Plate/Sheet/Strip |

>4.75~25 |

≤1035 |

≤725 |

≥30 |

HRC≤ 25 |

--- |

--- |

--- |

||||||

Plate/Sheet/Strip |

≤ 0.25 |

Standard

Heat Treatment

|

≥1240 |

≥1035 |

MV |

HRC≤ 36 |

--- |

--- |

--- |

|||||

Plate/Sheet/Strip |

>0.25~25 |

≥1240 |

≥1035 |

≥12 |

HRC≤ 36 |

--- |

--- |

--- |

||||||

Plate/Sheet/Strip |

≤ 0.38 |

≥965 |

≥795 |

≥5 |

--- |

655 |

≥23 |

--- |

||||||

Plate/Sheet/Strip |

>0.38~0.62 |

≥965 |

≥795 |

≥5 |

--- |

655 |

≥23 |

4 |

||||||

Plate/Sheet/Strip |

>0.62~25 |

≥1000 |

≥825 |

≥5 |

--- |

690 |

≥23 |

4 |

||||||

Standard Number |

Variety |

Heat Treatment |

℃ |

Tensile Property |

||||||||

MPa |

MPa |

% |

||||||||||

Q/3B 4052 |

Capillary Tube |

Solid Solution |

20 |

≤ 1070 |

≤ 655 |

≥ 30 |

||||||

Standard Heat Treatment |

20 |

≥ 1275 |

≥ 1035 |

≥ 12 |

||||||||

Remark: The whole tube tensile specimen is used |

||||||||||||

Standard Number |

Variety |

Heat Treatment |

℃ |

Tensile Property |

|||||||

MPa |

MPa |

% |

% |

||||||||

GJB 2611A |

Cold Drawn Rod |

Standard

Heat

Treatment

|

20 |

≥ 1270 |

≥ 1030 |

≥ 12 |

≥ 15 |

||||

650 |

≥ 1000 |

≥ 860 |

≥ 12 |

≥ 18 |

|||||||

GJB 3527 |

Cold Drawn Wire for Springs |

20 |

≥ 1270 |

≥ 1035 |

≥ 12 |

-- |

|||||

Standard Number |

Variety |

Heat Treatment |

℃ |

Hardness |

Durability |

||||||

GJB 2611A |

Cold Drawn Rod |

Standard

Heat

Treatment

|

20 |

MPa |

r/h |

% |

|||||

650 |

HBW≥ 345 |

--- |

--- |

--- |

|||||||

GJB 3527 |

Cold Drawn Wire for Springs |

20 |

--- |

690 |

≥ 23 |

≥ 4 |

|||||

Standard Number |

Variety |

Heat Treatment |

℃ |

HBC≥ 32 |

--- |

--- |

--- |

||||

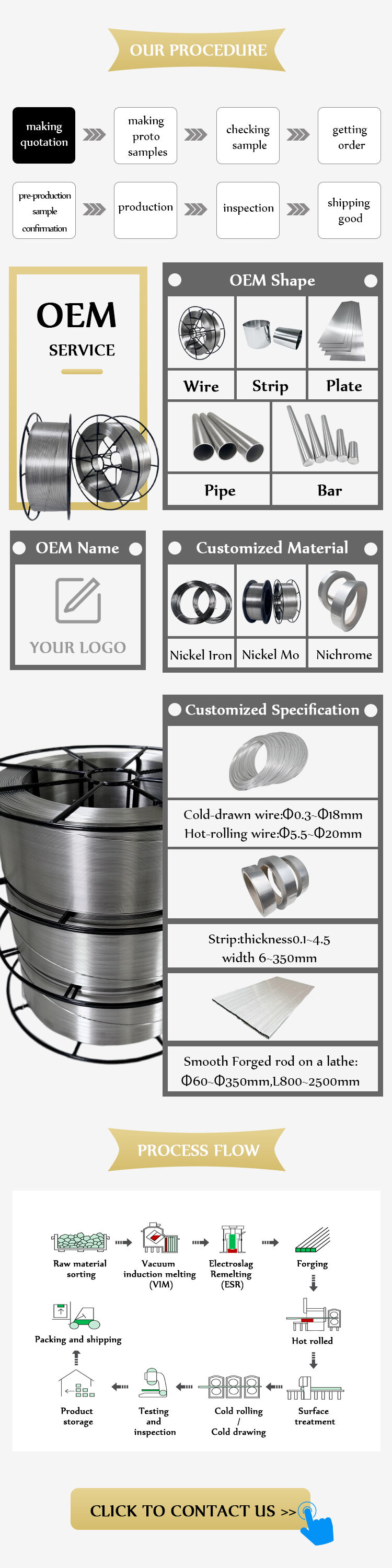

KX ALLOY

The UNS N07718 UNS N06625 Alloy 718 Rounded Lawyers Inconel 625 Rounded Lawyers coming from KX-Alloy is the ideal option for your commercial requirements. Created coming from costs high top premium products such as natural nickel, this rounded lawyers is developed towards endure higher severe problems temperature levels.

Great for utilize within incredibly destructive atmospheres along with outstanding rust protection residential or commercial homes. Due to its own outstanding energy is technological it is perfect for requests that needed higher tensile resilience stamina.

The Inconel 625 Rounded Lawyers Inconel 718 cost coming from KX-Alloy are extremely affordable provides outstanding worth for cash. Whether you are searching for a solitary rounded lawyers or even a mass purchase, you can easily make sure that you're obtaining the offers is finest feasible.

Whenever it concerns high top premium, this wases initially prices. Thoroughly crafted utilizing production is cutting edge goes through extensive quality assurance examinations towards guaranteed that it satisfies the very best demands.

Offered in a selection of dimensions towards fit your choices, creating it a flexible choices for lots of requests. Along with its own resistances is excellent towards heats, It is ideal for utilize in markets such as aerospace, chemicals, oils gases.

Therefore, if you are searching for a dependable top quality rounded lawyers that can easily endure also the harshest of atmospheres, look no more compared to KX-Alloy's UNS N07718 UNS N06625 Alloy 718 Rounded Lawyers Inconel 625 Rounded Lawyers. Along with its own unbeatable mix of high top premium, efficiencies, worths, it is the ideal option for your commercial requirements.

Copyright © Danyang Kaixin Alloy Material Co., Ltd. All Rights Reserved - Privacy Policy - Blog