|

C

|

Mn

|

Fe

|

Si

|

Cu

|

Ni

|

Co

|

|

≤ 0.02

|

≤ 1.0

|

4.0-7.0

|

≤ 0.08

|

≤ 0.5

|

≧ 50.0

|

≤ 2.5

|

|

P

|

S

|

Cr

|

Mo

|

W

|

V

|

|

|

≤ 0.04

|

≤ 0.03

|

14.5-16.5

|

15-17

|

3.0-4.5

|

≤0.3

|

|

|

Kakapalan

|

8.9g / cm3

|

|

Temperatura ng pagkatunaw

|

1325 1370-℃

|

|

pakete

|

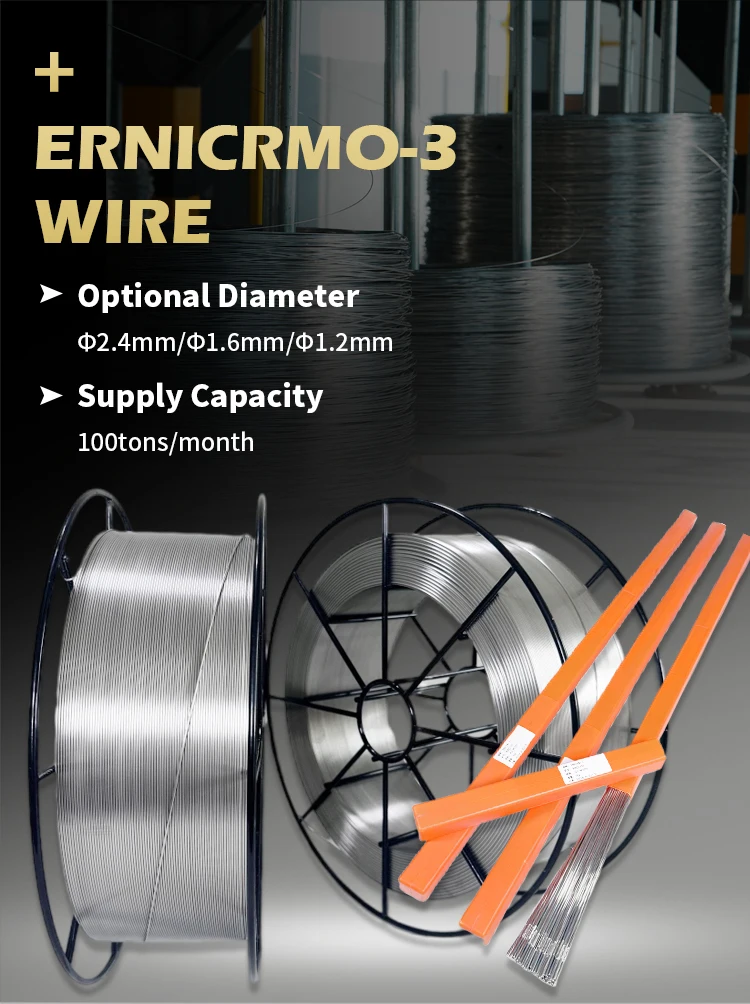

Welding Wire Diameter

|

Pinahihintulutang Paglihis

|

||

|

patayong bar

|

1.6,1..8,2.0,2.4,2.5,2.8,3.0,3.2,

4.0,4.8,5.0,6.0,6.4 |

± 0.1

|

||

|

Welding Wire Coil

|

+ 0.01

-0.04 |

|||

|

Wire Reel

Diameter 100mm at 200mm |

0.8,0.9,1.0,1.2,1.4,1.6

|

|||

|

Wire Reel

Diameter 270mm at 300mm |

0.5,0.8,0.9,1.0,1.2,1.4,1.6,2.0,

2.4,2.5,2.8,3.0,3.2 |

|||

|

Ang welding wire ay maaaring gawin sa iba pang laki, deviations at package gaya ng napagkasunduan ng parehong partido

|

||||

|

Pinapayagan ang paglihis ng ±0.1 diameter kapag ginamit para sa hand-filled wire

|

||||

|

Diameter ng Wire Reel

|

100

|

200

|

270,300

|

|

Maluwag na Diameter

|

60 ~ 380

|

250 ~ 890

|

380 ~ 1300

|

|

Warp Pitch

|

≤13

|

≤19

|

≤25

|

Copyright © Danyang Kaixin Alloy Material Co., Ltd. Lahat ng Karapatan ay Nakalaan - patakaran sa paglilihim - Blog